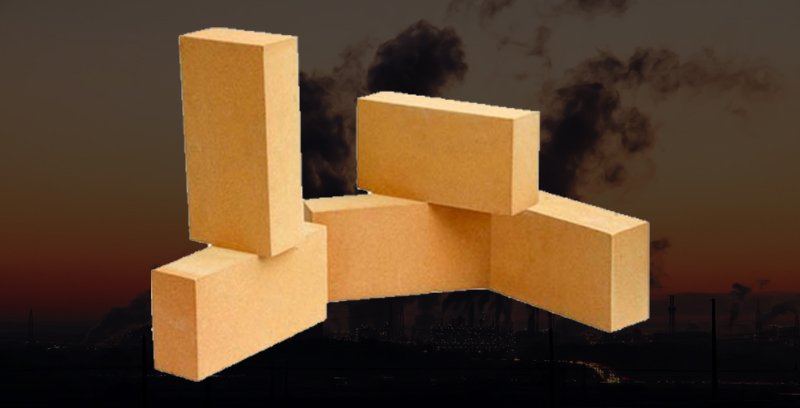

Refractory fire bricks

A fire brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces. A refractory brick is designed mainly to withstand high heat, but should also usually have a low thermal conductivity to save energy. Usually dense bricks are used in applications with extreme mechanical, chemical, or thermal stresses, such as the inside of a wood-fired kiln or a furnace, which is subject to abrasion from wood, fluxing from ash or slag, and high temperatures. Dense refractory bricks have a high thermal mass which is sometimes a useful property in that they will retain heat eg in a pizza oven after the fire has been taken out. Kiln bricks are made by firing a clay based composition in the kiln until it is partly vitrified, and for special purposes may also be glazed. Refractory bricks usually contain 30-40% alumina and the primary raw material is usually chamotte with other materials. The maximum service temperature increases with increasing alumina content and kiln bricks can be obtained with an alumina content of 80% and above.

Refractory Bricks Introduction

Refractory materials are generally divided into two kinds, namely, unshaped refractories and stereotypes refractories. Unshaped refractories, also known as castables, are made from a variety of aggregates or aggregates and one or more binders, which must be mixed with one or more liquids and with Strong liquidity. Stereotypes refractories generally refers to refractory bricks, the shape of the standard rules, can also be built according to the need for temporary processing.

Refractory brick is called fire brick. Refractory materials made of refractory clay or other refractory materials. The color is pale yellow or brownish. Mainly used for smelting furnace, the resistance of 1,580 ℃ -1,770 ℃ high temperature. Also called fire brick. A refractory with a certain shape and size. According to the method and method can be divided into burnt brick, unburned brick, fused brick (cast brick), fire insulation brick; According to the shape and size can be divided into standard brick, ordinary brick,special brick and so on. Can be used as building kilns and a variety of thermal equipment, high temperature building materials and structural materials, and at high temperatures can withstand a variety of physical and chemical changes and mechanical effects. Such as refractory clay brick, high alumina brick, silica brick, magnesia brick and so on.

Refractory Bricks Features

Own attribute

1.Chemical composition: the main ingredients determine the quality and characteristics of the refractory.

2.The bulk density: unit volume weight, density is large, indicating good density, strength may be high, but the thermal conductivity may be large.

3.Apparent porosity: did not do specific requirements, but as a manufacturer must strictly control the sensible porosity.

4.Load softening temperature: also known as high temperature load began to deformation temperature, this parameter is very important, marking the high-temperature resistance of materials.

5.Thermal shock resistance: the ability to resist sudden changes in temperature without being destroyed.

6.Compressive strength: the maximum pressure capacity to withstand (ambient temperature).

7.Bending strength: the ability to withstand shear pressure.

8.The linear rate of change: also called a "burn line" change, or "residual line change", which means that each time under the same temperature in the volume of expansion and contraction changes, and if every expansion contraction is the same, we define such a linear rate of change of 0.

Physical and chemical properties

1.Wear resistance.

2.Thermal conductivity: unit temperature gradient conditions, through the material per unit area. of the heat flow rate, with the porosity.

3.Impact resistance: impact resistance is good, long service life.

4.Slag resistance: at high temperatures to resist the role of slag erosion and not be destroyed.

PATENT PRODUCT

- Registered for “PATENT” of Novel Roller Refractory Supporting Block and “DESIGN” for the same.

INNOVATION

- We have Innovation in our DNA , which Proved by Winning National Award for Innovation and Various Other Innovative Products have been Developed by our R&D Activities.

APPLICATION ORIENTED SOLUTION

- Shah has all it takes to offer customized application oriented solution in blending. Mixing and firing.

OUR EXPERT TEAM

- We have highly qualified. Experienced and dedicated team to deliver proficient and indigenous products.

INFRASTRUCTUE

- Most advanced and superior technology available.